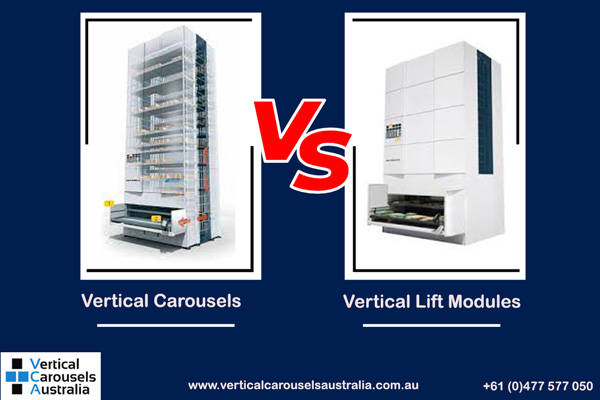

Vertical Modules and Vertical Carousels are two types of automated storage solutions that can help businesses enhance their storage and retrieval management. Furthermore, these systems allow inventories to be stored vertically rather than horizontally. You won’t have to worry about storing more stuff in one location because there won’t be any human interference.

Because there are so many storage systems to choose from, they are divided into two categories: Vertical Lift Modules/Vertical Lift Machines (VLM) and Vertical Carousels. Here, we’ll look at both their similarities and differences to help you decide which one is right for you.

Benefits of Vertical Carousels and Vertical Lift Module/Machine

Both the automated vertical carousel and the vertical lift machine give the following services to people:

- Slow and medium velocity items can benefit from high-density storage and retrieval solutions.

- Automated delivery of ordered products to waist height for easy pickup.

- For enhanced security, the area is completely enclosed with secured access.

- Utilizes the facility’s vertical space to maximise storage.

How do they store items?

(a) Vertical Lift Module/vertical Lift Machine

A mechanical extractor is positioned in the centre of the vertical lift module/vertical Lift machine, which is made up of two tray columns. The extractor moves up and down between the trays, automatically locating the articles that meet the criteria. This equipment resembles an elevator, having doors that open both forwards and backwards.

(b) Vertical Carousels

They’re made up of a succession of tray-like carriers that are attached to a chain drive in permanent locations. A motor controls or powers the vertical carousel’s movement, which sends the carriers in a vertical looping pattern. They have the same forwards and backwards motion as a Ferris wheel.

How do they measure?

(i) The Footprints

The footprints of both technologies are nearly the same width. There isn’t much of a difference. Vertical lift machines, on the other hand, can be half as big as vertical carousels when it comes to depth. As a result, vertical carousels have a smaller total footprint.

(ii) Height

Vertical lift modules begin at 8 feet tall and can be put up to 98 feet tall. Vertical carousels, on the other hand, can start at a lower height of merely 7 feet and rise to a maximum height of 32 feet.

Although both of these machines can reach your ceiling, they are not required to be as tall as they should be. The conclusion is that the taller the equipment, the slower it operates. So it’s entirely up to you to figure out the proper height to strike a balance between its operations and goals (space-saving).

(iii) Loading Capacity

In Australia, an updated version of automated vertical carousels can hold up to 1430 pounds per carrier. VLMs, on the other hand, can be equipped with special trays that can hold loads of up to 2200 pounds each.

Vertical carousels are difficult to fit with cranes and ergonomic lifts, which is the only main difference between the two devices. So, if you need to store large objects, Vertical lift modules are the ideal option.

Which would be a better option for your warehouse?

VLMS and vertical carousels are appropriate for a range of applications due to high similarities in structure, mode of operation, and objective. Keeping these considerations in mind, however, might assist you in deciding which system is best for you.

Vertical Lift Modules are most effective when:

- Up to 100 feet of ceiling height is possible.

- Parts of varying sizes and weights are kept.

- Inventory is constantly changing.

- For operator safety, heavy loads necessitate the use of lifts.

Vertical Carousels function best in

- Rooms with a ceiling height of fewer than 25 feet.

- The things in the storage area are all of the same sizes.

- Items that can be picked up without the use of lifts or other forms of assistance.

Both of these devices are the greatest in their own right when it comes to material handling. However, selecting them based on your personal preferences can be difficult. With the distinctions between the two storage systems discussed above, picking an automated storage option is no longer rocket science.